Hidden in Plain Sight: Sustainable Infrastructure for Thriving Communities

Building the Backbone of the Circular Water Economy

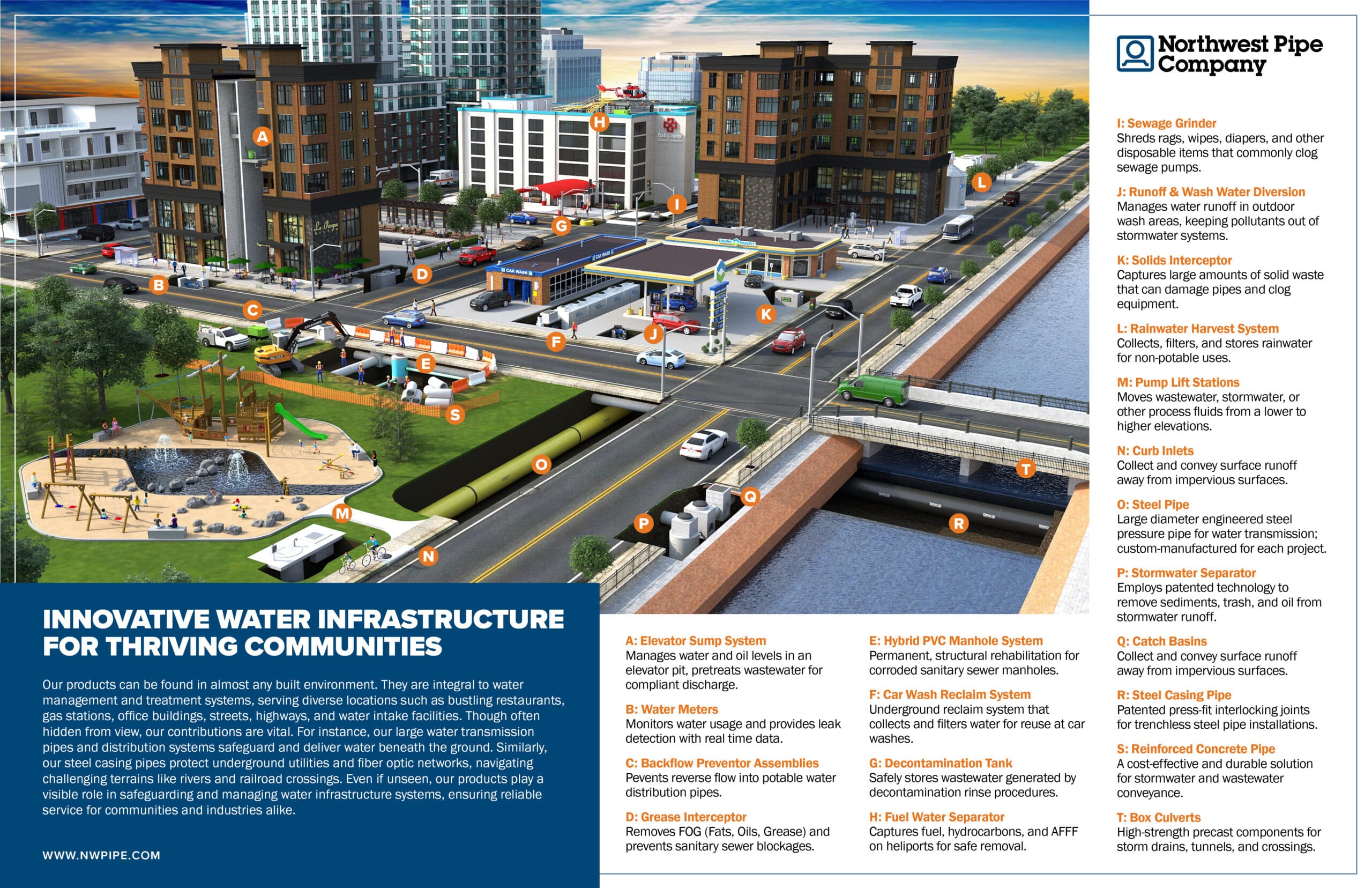

This Earth Day, we’re highlighting the often-unseen infrastructure that supports both a sustainable environment and the communities we call home. At Northwest Pipe Company, our products play a foundational role in closing the loop in the water cycle—conveying, measuring, treating, and protecting our most vital resource—while enabling resilient growth in cities and towns across North America.

The systems we engineer and manufacture are designed to move water through every stage of the cycle, contributing to a circular water economy that reduces waste and conserves resources, emphasizes reuse and recycling, and restores and protects the natural environment. Here are a few examples of how NWP solutions connect the three R’s of the circular water economy:

Reduce

Fundamental to reducing waste in the water cycle is efficient water conveyance. Our engineered steel pipe conveys raw water to treatment plants and carries clean, treated water supplies for distribution in communities—reliably and without water loss. Built with leaktight joints and resilient materials, these systems effectively move millions of gallons a day at high pressure across long distances, enabling sustainable population growth and reducing reliance on less sustainable water sources.

Another example is the use of steel water pipe or reinforced concrete pipe (RCP) to enclose aging open canals. Piped systems significantly reduce water loss due to seepage and evaporation compared to open, unlined canals, conserving water for agricultural and industrial applications.

Once treated water reaches communities, water meters play a key role in measuring usage and detecting leaks at critical points in the system. Backflow preventers ensure the safety of potable supplies by stopping reverse flow and preventing cross-contamination.

Reuse & Recycle

The next phase in the water cycle is almost exclusively out of sight—and by design. Wastewater from businesses like restaurants, grocery stores, and gas stations relies on pretreatment technologies such as our gravity grease interceptors and oil-water separators to remove harmful sediments, fats, oils, and greases before discharge. This step protects sanitary sewer systems and treatment plants from clogs and damage, reducing pollution and safeguarding municipal water infrastructure.

Car wash water reclaim systems offer a specific example of recycling technology at this stage. These underground systems, comprising a series of precast vaults and an oil-water separator, capture and filter wash water for clarification and reuse.

Pump lift stations maintain the movement of wastewater from lower to higher elevations within the system. Lined RCP and manholes provide corrosion protection and leak-free junctions that extend service life and reduce inflow and infiltration—factors that can overwhelm equipment and reduce capacity at treatment facilities.

Once wastewater reaches the treatment plant, Park Process dewatering equipment assists in solids separation and filtration, processing water for reuse in irrigation, industrial applications, and groundwater recharge—or preparing it for advanced purification and recycling into potable water.

Restore

The restore phase of the circular water economy focuses on protecting and revitalizing natural environments. Precast stormwater quality products—including filter basins, runoff diversion systems, hydrodynamic separators, trash interceptors, and floatable collection screens—act as a first line of defense against pollution. Integrated into low-impact development strategies, these products are easily installed in areas like roadways, parking lots, and along conveyance systems to protect rivers, lakes, streams, and coastal habitats.

Reinforced concrete box culverts (RCB) are one of the few visible infrastructure components on this list. Used to build bridges and overpasses, they maintain the hydrology of waterway crossings while minimizing impacts on aquatic ecosystems. RCB is also used for wildlife crossings, providing safe passage for animals above or below highways and improving safety for both commuters and wildlife.

Returning underground, our Permalok® steel casing pipe supports trenchless installation—a construction method that avoids large-scale excavation. This reduces surface disruption, preserves sensitive environments, and enables infrastructure installation beneath rivers, roads, and developed areas.

Empowering Sustainable Growth—Quietly and Effectively

While our infrastructure is often hidden underground or behind the scenes, it plays a very visible role in supporting sustainable, livable communities. From the water you drink to the systems that manage wastewater and protect against flooding, our products are essential to the health and resilience of urban and suburban areas—and to the environment.

Every day, our engineered systems make it possible for cities to grow responsibly, for clean water to reach families safely, and for natural resources to be protected for future generations. Whether we’re supporting a wastewater treatment facility in a rural town or helping a growing city manage stormwater runoff, our solutions directly contribute to a circular water economy and a more sustainable world.

>

>