We manufacture each piece of engineered steel pipe to the custom requirements of your project. The high tensile strength of steel and its natural resilience to seismic events make it the workhorse that has been around since the 1850s—and still going strong. Northwest Pipe is the leading manufacturer of engineered steel pipe in North America for many reasons—our quality standards, unrelenting drive in innovation, and ability to solve client challenges are a few of those reasons.

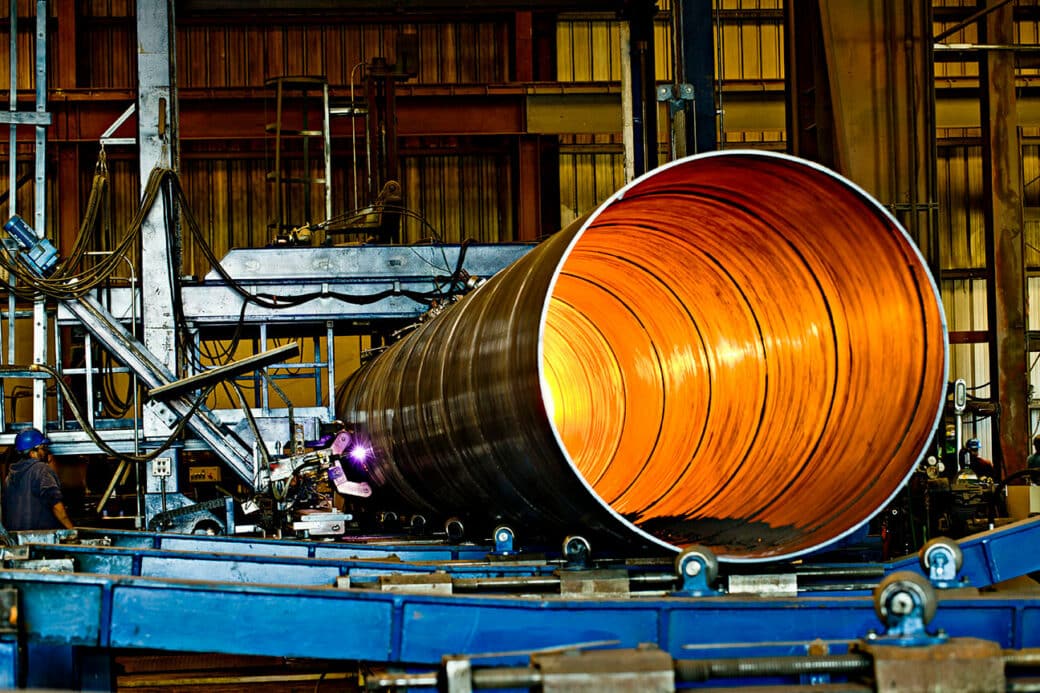

Manufactured in accordance with AWWA Manual M11, we manufacture spiralweld pipe, rolled-and-welded straight seam pipe, and custom pipe from 12” to 156”, and larger if needed. Our engineering team can readily answer any question about a new pipeline or rehabilitation project you are facing.

Capabilities

MoreMoving water from its source to civilization is not a new concept. For thousands of years, pipe has been the trustworthy transport to supply water to growing communities. The basic principle of delivering water has not changed over the years, but the innovation behind each piece of steel water pipe is a demonstration of modern manufacturing.

Joints

MoreSelecting the appropriate joint is critical to any pipeline project. Northwest Pipe leads the industry in joint technology and scientific analysis to construct joints that maintain integrity for the service life of your project. Depending on pipe functionality and site conditions, your team will select either an unrestrained joint, which has a gasket, or a welded restrained joint. Both are designed to provide a permanent watertight seal.

InfraShield® Joint System - Geohazard Resistant Steel Pipe (GRSP)

MoreThe InfraShield® Joint System builds upon the time-tested lap-welded bell-and-spigot joint design by adding a small projection in the steel pipe wall that effectively transfers tensile and compression forces caused by ground-induced actions. It is simple in design, yet powerful in performance. Our concept improves the mechanical response of steel pipe during a seismic event, differential settlement, landslide, or in zones with potential liquefaction hazards.

Linings

MoreWater Transmission pipelines achieve incredibly long lifespans with the use of modern protective linings. These long-standing protective systems prevent corrosion, an electrochemical process that oxidases steel in the presence of moisture and oxygen. Our factory-applied protective linings isolate the steel pipe while ensuring safe water delivery.

Coatings

MoreApplied to the pipe exterior, coatings are the first line of protection against corrosion and other elements. Coatings prohibit corrosion, which can occur from corrosive soils, dissimilar metals, bacteria, stresses, or stray electrical current in the ground. To further the long performance life of steel pipe, Northwest Pipe offers both dielectric and chemical inhibitor pipe coatings such as polyurethane and tape.