Joints

Selecting the appropriate joint is critical to any pipeline project. Northwest Pipe leads the industry in joint technology and scientific analysis to construct joints that maintain integrity for the service life of your project. Depending on pipe functionality and site conditions, your team will select either an unrestrained joint, which has a gasket, or a welded restrained joint. Both are designed to provide a permanent watertight seal.

Our industry-leading pipe joints minimize water loss and maintain high-carrying capacity. The resilient nature of steel pipe also delivers joint soundness without perfect trench grading or soil stability.

Unrestrained Joints

O-Ring Joint

The routinely used gasketed joint, or O-Ring Joint, provides an economical, non-welded method for joining steel water pipe without a reduction in the rated working pressure. The O-Ring gasket is seated into a rolled groove formed at the spigot end of a pipe cylinder. The other end of the pipe is expanded into a bell shape for pipeline joining. Inserting the spigot into the bell compresses the O-Ring and forms a watertight seal.

The VanderSeal Joint

Named after one of our engineers, the VanderSeal joint is a rubber compression type joint for steel pipe, suitable for both water and sewage conveyance. The bell end of the pipe includes a formed recess to retain a molded rubber gasket. When a plain end spigot pipe is inserted into the bell, the gasket compresses against the steel surfaces to provide a watertight seal.

The VanderSeal joint eliminates gasket dislodgement during field installation and facilitates easy field installation. The unique shape of the gasket features a reinforcing spline that assures positive retention in the cold-formed bell, thus preventing dislodgement during spigot insertion. The gasket is self-centering and is not dependent on internal hydrostatic pressure, making it excel in a wide range of field conditions.

With a plain-end spigot pipe, the joint has greater flexibility and can accommodate a 0.75 inch standard pull allowing minor deflection angles and pipe offsets to be incorporated into the pipeline layout.

Benefits of Unrestrained Joints

- Economical, non-welded method of joining buried steel water pipe.

- Quick installation with no welding time.

- Non-rigid joints accommodate differential ground settlement after pipeline installation.

- Joint flexibility allows angular deflection for long-radius curves and minor field alignment changes.

- Formed integrally into the pipe cylinder, the joint has strength equal to that of the pipe itself.

- Suitable for diameters up to 78 inches.

Restrained Joints

Bell-and-Spigot Lap Weld Joint

Restrained joints provide reliable thrust resistance for buried pipe with working pressures in excess of 400 psi. These joints can withstand designed or unexpected surges associated with high-pressure pipelines. Combining a joint pull of 2 degrees with a 5-degree miter cut to the bell end allows up to 7 degrees of deflection per joint, ideal for eliminating elbows, laying steel pipe on a radius, or adjusting for profile changes.

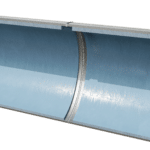

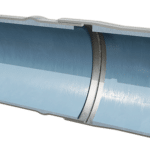

Butt-Strap Joint

Butt-strap joints feature a two-piece roll formed strap that joins pipe with two longitudinal welds in addition to a circumferential fillet weld. Field teams can weld the joints from the inside, outside, or both.

Butt-Weld Joint

Butt-weld joints are a single-weld circumferential joint that allow up to 5 degrees deflections with a miter cut on one end of a pipe, or up to 10 degrees deflection by joining two mitered pipe ends. A full penetration weld is required for this type of joint.

Restrained joints are required for areas where thrust loads or pipe movements must be overcome such as bends, reducers, surges or valves.

Benefits of Restrained Joints

- Northwest Pipe welded joints are available for all pipe diameters

- Pipe can accommodate working pressures over 400 psi

- Can be welded ID or OD

- Easy assembly and fit-up in the field

Other Joints

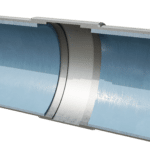

InfraShield® Seismic Resilient Joint System

The InfraShield® Seismic Resilient Joint System builds upon the time-tested lap-welded bell-and-spigot joint design by adding a small projection in the steel pipe wall that effectively transfers tensile and compression forces associated with seismic events. It is simple in design, yet powerful in performance. The projection transfers force into the pipe wall without overstressing the lap-welded joint. Explore the System.

Carnegie Joint

Carnegie-bell-and-spigot gasketed joints provide an economical, non-welded method for joining bar-wrapped concrete pressure pipe and steel water pipe. Carnegie-bell-and-spigot joints are suitable for a variety of buried pipeline applications and can also be welded. With over five decades of use, the Carnegie joint has proven to be reliable in performance and economical for field installation.

Testable Carnegie Joint

Testable Carnegie Joints are very similar to traditional Carnegie Joints but have an extended spigot with two gaskets to allow space to accommodate a drilled portal to test pressure, which allows the contractor to confirm joints are watertight.

Custom Solutions & New Innovations

Northwest Pipe Company manufactures a full range of custom fittings and non-traditional joints including mechanical couplings and flanged joints.