Quick to Install, Maintenance-Free Corrosion Protection for Wastewater Structures | 100% Made in the USA

Geneva Pipe and Precast’s Composite FRP Rehab Panels are easy to install and maintenance-free. The panels are ideal for rehabilitating existing large wastewater structures as well as for providing a corrosion-resistant lining to new structures, extending the service life by decades.

Our Composite FRP Panels consist of a PP honeycomb core with polyester fleece backing and a thick outer layer of corrosion-resistant FRP. The panels come pre-drilled and ready to be mechanically fastened to the walls of an existing concrete structure. Once the panels are securely mounted, the void between the panels and the walls is filled with high-strength grout to provide additional strength to the system. Seams between the panels and all fastener heads are sealed in a three-step process by qualified applicators providing seamless protection from the corrosive environment of hydrogen sulfide gases.

Advantages

- Corrosion resistant

- Economical and reliable solution

- Field inspected, qualified, and engineered system

- Quick and easy installation

- Maintenance-free

- Customizable design

- Engineering and installation education and support

- Proven performance

- Third-party tested for corrosion resistance

- High-quality assurance

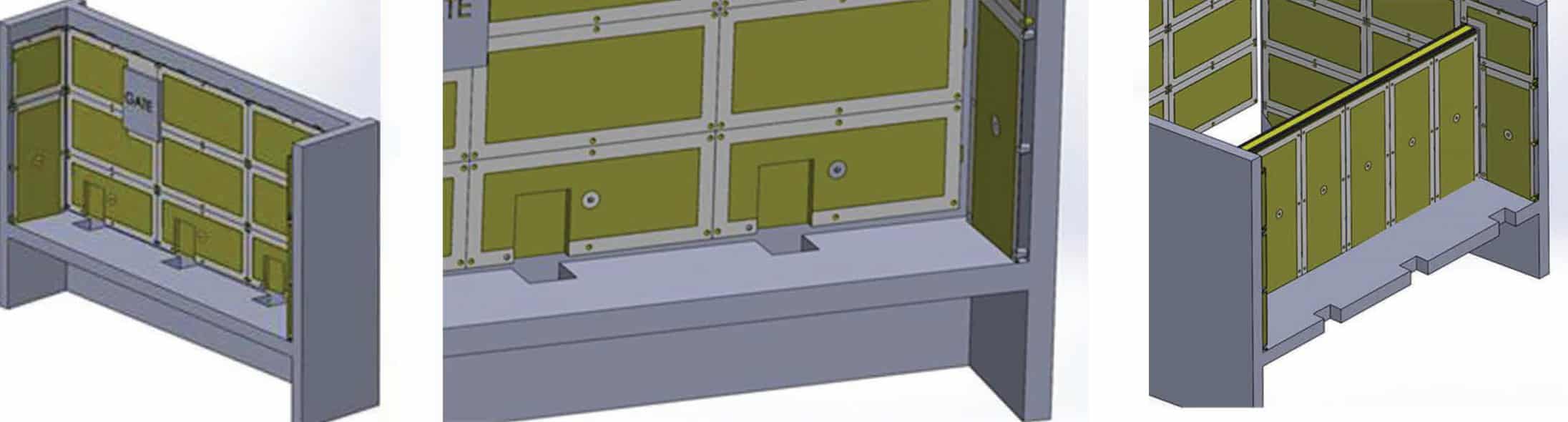

3D Modeling

Using a 3D scanner, the interior of the structure being rehabilitated will be scanned to obtain a representative digital model. Geneva’s Engineering team will evaluate the model based on the digital visuals and will dimensionally compare it to the as-built drawings of the structure. After a thorough analysis, if significant deviations in interior dimensions exist, or significant structural deterioration is evident, Geneva’s Engineering team will report their findings to the owner and recommend third-party engineering review to evaluate the condition further.

If the structure is suitable for rehabilitation, Geneva’s Engineering team will design a panel layout to fit the existing structure’s configurations. From top to bottom, the access hatch locations, pump discharge pipe, inlet pipes, odor control pipes, flow channels, and other features are identified with proper sealing details provided for each individual structure.

Upon completion, the entire structure is scanned again. Geneva’s Engineering team will inspect all work performed and either accept it or provide a statement of remedial work in specific areas. Once the work has been accepted the owner will be provided with a manufacturer’s acceptance document and a digital image that can be used in the future to evaluate any changes in the structure.

Rehabilitate with Confidence

Composite FRP Panel materials have undergone third-party testing, and have a proven record of protecting concrete sanitary sewer structures against corrosion. Composite FRP panels are designed to be affixed to the existing walls of the structure with stainless steel concrete anchors. Panel joints are sealed against sanitary gases by bonding FRP E-Glass over all joints and fastener heads, creating a completely corrosion-resistant system.

Composite FRP Panel technology can also be used to rehabilitate curved structures, including large-diameter precast lift stations and cast-in-place clarifiers, providing an alternative to the field-applied coating method of rehabilitation. Contact us to inquire about using Composite FRP Panels on curved structures in your collection system or wastewater treatment plant.

Corrosion Protection for New Construction

Composite FRP Panels are also an ideal solution for protecting new concrete wastewater structures from corrosive sanitary sewer gases. Quick and easy installation, as well as a maintenance-free service life, show that our FRP panel system is a cost-effective way of adding longevity to newly built wet wells, vaults, and other wastewater structures of any scale.

Applications

- Rehabilitation

- Sanitary Sewer

- New Construction

Testing

- Pickle Jar – Weight Change (SSPWC 211-2)

- Pickle Jar – Tensile Strength (ASTM D638)

- Pickle Jar – Hardness (ASTM D2240)

- Flexural Strength (ASTM D790)

- Abrasion (ASTM D-4060)

- Compression (ASTM D-695)