Permalok® Radial Bending Joint (RBJ)

The patent-pending Permalok® Radial Bending Joint (RBJ) enables steel pipe to be installed along a curved radius in microtunneling applications. This innovative technology represents a groundbreaking advancement in trenchless construction and a first in the industry.

Permalok® steel pipe is most often used as a casing pipe for utilities and excels in trenchless jacking applications. The press-fit machined joints reduce field time by eliminating the need for butt-weld joints. The RBJ provides the same reliability, unparalleled speed, and consistency as our other Permalok® joint designs, with the added flexibility of installing along a curve.

This improvement creates more opportunities for maneuverability in congested tunnel alignments, allowing the pipe path to bend in any direction around existing utility lines, monuments, and building foundations. Additional benefits to the contractor include a smaller jobsite footprint, fewer shafts, and more precise execution of tunneling over longer distances.

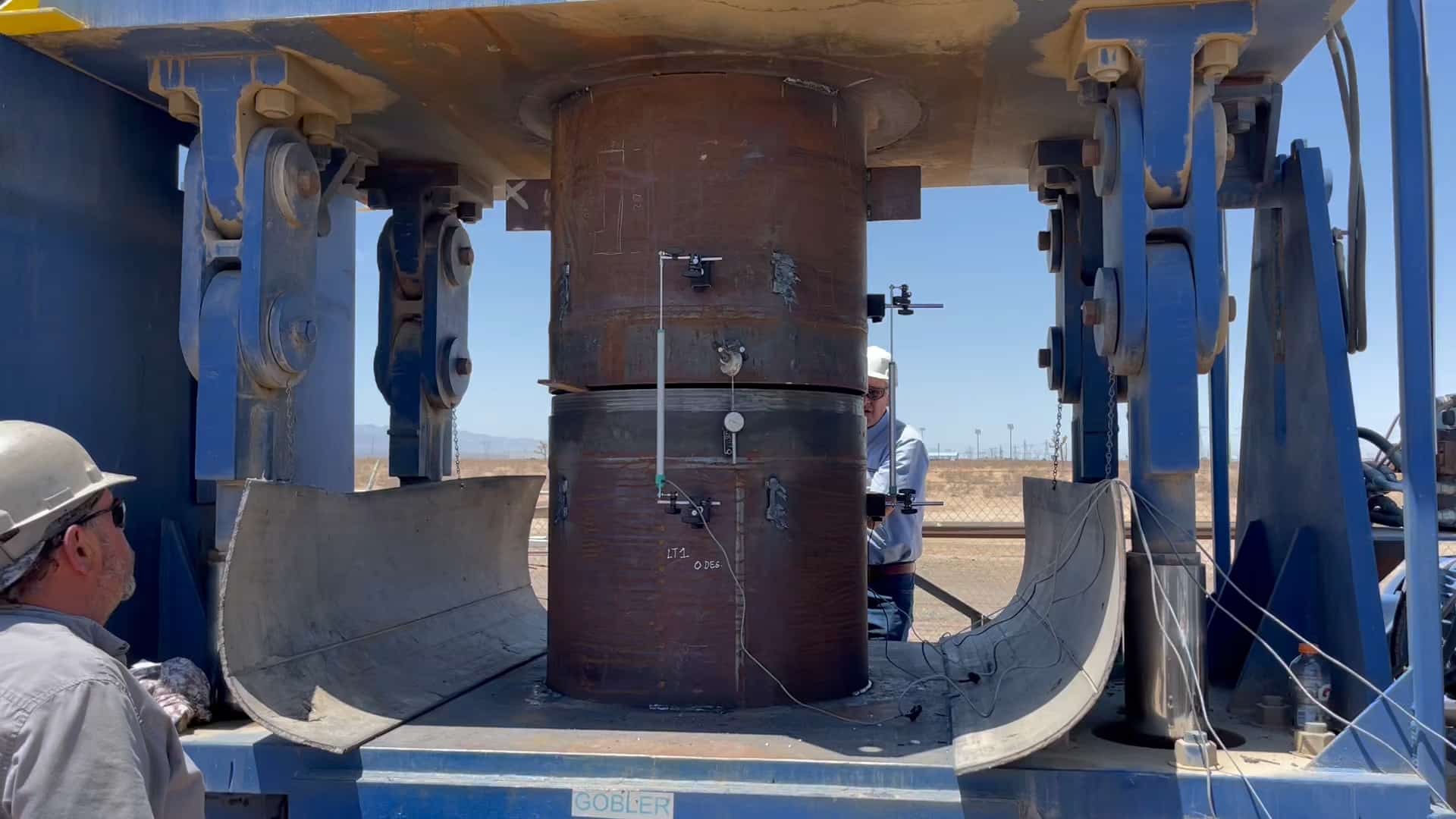

To solidify the joint’s validity, the RBJ has undergone Finite Element Analysis at the University of Thessaly, Department of Mechanical Engineering, as well as extensive product testing at our steel pipe manufacturing facility in Adelanto, California.

Following the successful development and installation of the Permalok® AB and PR joints, the RBJ follows the exacting specifications and precision engineering of the original Permalok® press-fit machined connection, which reduces field time by eliminating butt-weld joints. The result: a shortened install duration and lower field costs, all with the proven benefits of steel pipe.